How We Make Maple Gold

Ever wonder how real Vermont maple syrup is made? Below you’ll learn how we make premium Gold Rush Maple Syrup and by the end you’ll understand why we refer to maple syrup as Gold!

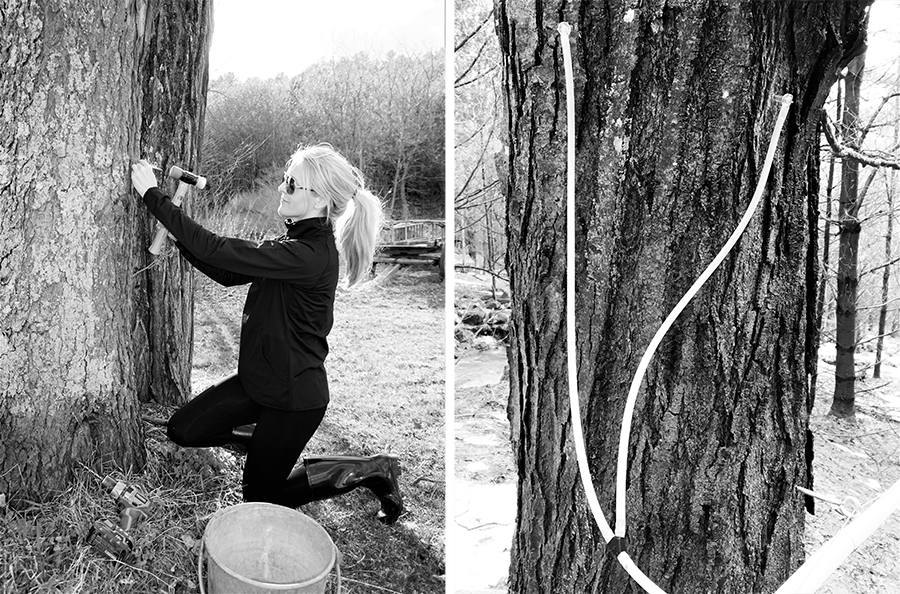

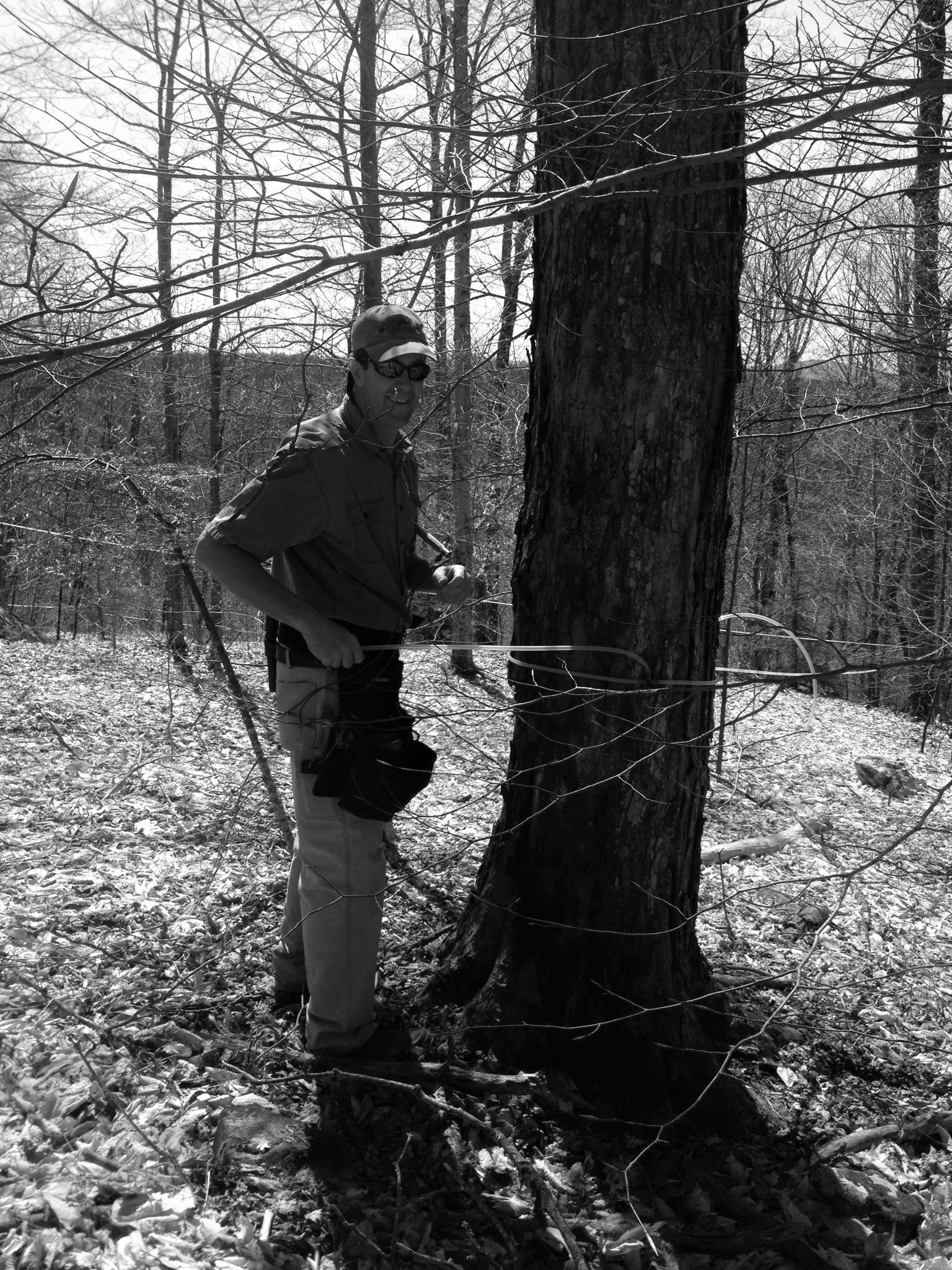

What: Sugar Maple Tree, Acer Saccharum

Where: Northeastern continental United States

When: Typically in March and April, good weather for sap production are freezing temperatures at night and temperatures in the 40’s with sun during the day. The freezing and thawing cycle causes pressure changes inside the tree which makes the sap flow.